Wastewater Department

Shipshewana’s wastewater treatment plant (WWTP) is a facility designed to clean and treat water that has been used in homes, businesses, and industries before it is safely released back into the environment. This used water, called wastewater, contains contaminants like human waste, food scraps, oils, soaps, and chemicals.

To help keep our system working properly, please do not flush any type of wipes (including baby wipes), even if they’re labeled as “flushable.” Also, avoid flushing dental floss, diapers, cooking grease, medications, or cotton products. These items should be disposed of in the trash. Thank you for your cooperation!

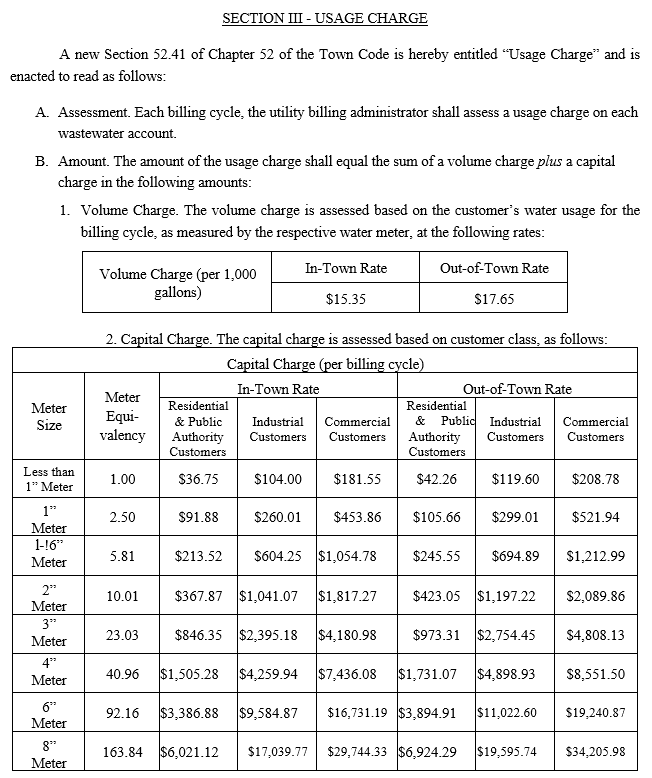

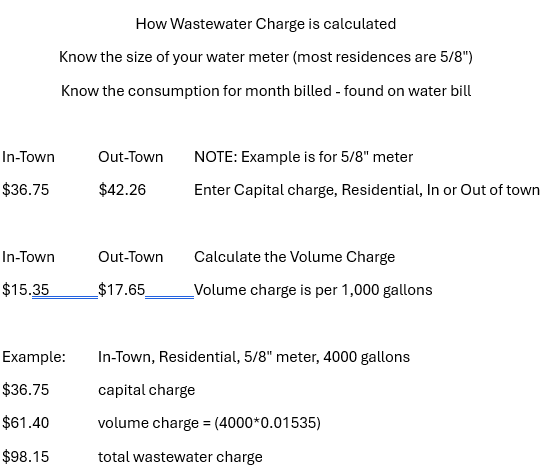

Important Update on Wastewater Rate Adjustment

We understand that recent questions have been raised regarding the increase in wastewater rates. We want to assure you that this decision was not made lightly.

The rate adjustment was a necessary step to address essential repairs and upgrades to our wastewater treatment plant—a project vital to the health and sustainability of our community infrastructure.

After extensive evaluation of all possible designs and funding alternatives, we’ve taken every measure to minimize financial impact on our residents:

- Secured grant funding that reduces the total loan amount by $3 million

- Obtained an $18 million SRF loan with 0% interest, saving residents millions over the life of the loan

- Partnered with the state to increase the local food and beverage tax, helping offset the need for additional rate increases

We want you to know that we truly understand the burden rate changes can create, and your concerns are heard. We remain committed to continuing our efforts to explore future options for rate reduction, once critical infrastructure needs have been met.

Without this funding, the necessary repairs could not proceed, potentially resulting in significantly higher costs and long-term consequences for Shipshewana residents. Investing in these upgrades now allows us to avoid greater expenses down the road—and uphold our responsibility to protect the well-being of our community.

Thank you for your understanding and continued support.